High Output.

High Output.

Reduces Pipe Consumption

Reduces Pipe Consumption

Good melt uniform and low melt temperature.

Good melt uniform and low melt temperature.

Superior end of Product.

Superior end of Product.

Since 1998 Vrundavan Plastic Engg. Works has been manufacturing state of the art Plastic Extrusion Plants. Presently we are recognized as the best Single Screw Extruder Manufacturers in India and many other parts of the world. It would not be wrong to say that we have revolutionized this industry with our machines in more ways than one. Our single screw extruders are currently a part of many workshops and factories.

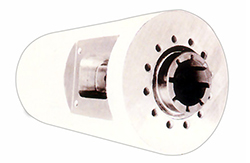

An Extrusion Plant is used to create specific shapes by forcing raw material through a die. At Vrundavan Plastic Engg, we specialize in manufacturing Plastic Extrusion Plants that are used in a wide spectrum of industries supplying semi-finished and finished plastic items. Our single screw extruders have been used by manufacturers for several years now. Not only can our extruder machines produce shapes but they also plastic moulds, pipes, granules, powder, sheets and so on which are so crucial for many of the manufacturing and packaging industries. All our extruder machines feature compact structure, high automation and ease of operation. Being prominent Single Screw Extruder Manufacturers, we provide the best extrusion technology to our clients.

Being a forerunner among other Single Screw Extruder Manufacturers, we have the capacity to customize our machines on the basis of size, raw material that is fed into it and the quantity it is required to produce. Our Single Screw Extrusion Plant is simple in design and best suited for small scale manufacturers. Our team of engineers and expert designers will not only custom-design the extruder for you, but also train your team in handling it and constantly assist in post-sales support. With each of our machines we move a step closer to achieving precision.

| MODEL | 30 | 40 | 45 | 50 | 65 | 75 | 90 | 120 | |

|---|---|---|---|---|---|---|---|---|---|

| Screw Diameter | mm | 30 | 40 | 45 | 50 | 65 | 75 | 90 | 120 |

| L : D Ratio | L/D | 22:1 | 26:1 | 28:1 | 28:1 | 30:1 | 30:1 | 30:1 | 30:1 |

| Output(Max. HDPE) | Kg/H | 4 - 6 | 16 - 20 | 20 - 30 | 25 - 35 | 50 - 75 | 80 - 100 | 150 - 180 | 250 - 300 |

| Motor | HP | 3 | 7.5 | 15 | 15 | 30 | 40 | 75 | 150 |

| MODEL | UNIT | 45/50-G | 65-G | 65-G1 | 75-G | 75-G1 | 75-G2 | 75-G3 | 90-G | 90-G | 90-G |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Screw Dia | mm | 50 | 65 | 75 | 75 | 75 | 75 | 75 | 90 | 90 | 90 |

| L:D Ratio | L/D | 32 : 1 | 32 : 1 | 32 : 1 | 32 : 1 | 32 : 1 | 32 : 1 | 32 : 1 | 32 : 1 | 32 : 1 | 32 : 1 |

| Max Output (Pipe) | Kg/H | 80 - 100 | 120 - 140 | 180 - 210 | 180 - 215 | 250 - 275 | 325 - 350 | 450 - 500 | 450 - 500 | 550-600 | 700-800 |

| Motor | HP | 30 | 50 | 75 | 75 | 100 | 125 | 150 | 150 | 200 | 300 |

Copyrights 2018, All Rights Reserved By Vrundavan Plastic Engg. Works